اسید اکریلیک (تثبیت شده) برای سنتز

| Formula | C3H4O2 |

| Chemical formula | CH2CHCOOH |

| Molar mass | 72.06 g/mol |

| Density | 1.05 g/cm3 |

| CAS number | 79-10-7 |

| HS Code | 29161100 |

| EC number | 201-177-9 |

| Storage | Store at 15 to 30° C |

| SDS | available |

| R phrase | R 10-20/21/22-35-50 |

| S phrase | S 26-36/37/39-45-61 |

| Odour | pungent |

| Form | liquid |

| Color | colorless |

| Explosion limit | 3.9 -19.8 vol % |

| Ignition temprature | 390 °C |

| Solubility in water | 1000 g/l (25 °C) |

| Solubility in ethanol | soluble (20 °C) |

| Flash point | 46 °C |

| Boiling point | 141°C (1013 hPa) |

| Melting point | – 13 °C |

| Vapor pressure | 4 hPa (20 °C) |

| Viscosity dynamical | 1.22 mPa *s(20 °C) |

| Saturation concentration | 12.6 g/m3 (20 °C) |

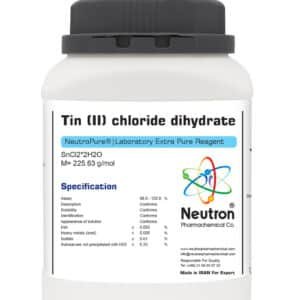

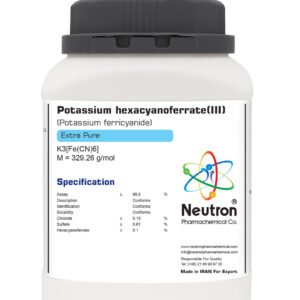

| Assay | ≥ | 99.0 | % |

| Appearance | Conforms | ||

| Solubility | Conforms | ||

| Identification | Conforms | ||

| Density | 1.048 to 1.050 |

Acrylic acid (stabilized) for synthesis is a clear to slightly yellow liquid with a sharp, acrid odor that is widely used as a key monomer in the production of polymers, coatings, adhesives, and various chemical intermediates. The stabilized form contains a small amount of polymerization inhibitor such as hydroquinone monomethyl ether (MEHQ) to prevent unwanted polymerization during storage and handling.

🏭⚗️ Production

Acrylic acid is industrially produced by catalytic oxidation of propylene in a two-step process, where propylene is first converted to acrolein and then oxidized to acrylic acid. The stabilized acrylic acid is obtained by adding polymerization inhibitors during or after production to ensure safe storage and to prevent spontaneous polymerization, which could otherwise cause heat and pressure build-up.

🔬 Properties

The chemical formula of acrylic acid is C₃H₄O₂ with a molar mass of approximately 72.06 g/mol. It appears as a clear to slightly yellow liquid and has a strong, pungent odor. Acrylic acid boils at around 141 °C and melts near 14 °C. It is completely miscible with water, alcohols, and many organic solvents. Due to its unsaturated carboxylic acid structure, acrylic acid is highly reactive and prone to polymerization, especially if not stabilized. The stabilized form resists spontaneous polymerization under normal storage conditions.

🧪 Applications

Acrylic acid is used extensively as a precursor in the manufacture of superabsorbent polymers, which are key materials in diapers and hygiene products. It is also utilized in the production of polyacrylic acids, adhesives, coatings, sealants, textiles, and water treatment chemicals. In chemical synthesis, acrylic acid serves as a valuable reagent for producing various polymers and crosslinked materials, making it essential in both industrial and research applications.

⚠️ Safety

Acrylic acid (stabilized) must be handled with care because it is corrosive, flammable, and can cause severe skin burns, eye damage, and respiratory irritation. Although the stabilized form reduces the risk of uncontrolled polymerization, exposure to heat, light, or incompatible substances may still cause hazardous reactions. Appropriate personal protective equipment including gloves, goggles, and lab coats should always be worn, and handling should be performed in well-ventilated areas or fume hoods. The compound should be stored in tightly sealed containers away from heat sources, sparks, and incompatible chemicals such as strong oxidizers and bases.