پلی اتیلن گلایکول 400

| Formula | HO(C2H4O) n H |

| Chemical formula | HO(C2H4O) n H |

| Density | 1.12 g/cm3 (20°C) |

| Molar mass | 380 – 420 g/mol |

| CAS number | 25322 -68-3 |

| HS Code | 39072011 |

| Storage | Store at 15 to 25 °C |

| SDS | available |

| Odour | almost oduorless |

| Form | liquid to viscose |

| Color | colourless |

| Ignition tempratue | 360 °C |

| p H value | 5 – 7 (100 g/l 20 °C) |

| Solubility in water | soluble 20 °C ) |

| Flash point | 240 °C (0 °C) |

| Boiling point | ~ 250 °C |

| Melting point | 4 – 8 °C |

| Vapour pressure | ~ 0.1hpa (20 °C) |

| Thermal decomposition | ~ 220 °C |

| Viscosity dynamical | 105 – 140 mPa*s (20 °C) |

| Viscosity kinematic | 97 -110 mm2/s (20 °C ) |

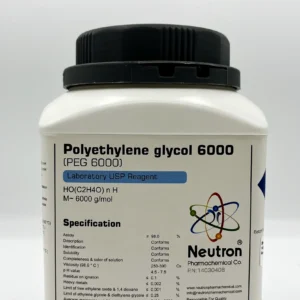

| Assay | ≥ | 99.0 | % |

| Description | Conforms | ||

| Identification | Conforms | ||

| Solubility | Conforms | ||

| Completeness & color of solution | Conforms | ||

| Viscosity (98.9 ° C ) | 6.8 – 8.0 | Cs | |

| p H value | 4.5 – 7.5 | ||

| Residue on ignation | ≤ | 0.1 | % |

| Heavy metals | ≤ | 0.002 | % |

| Limit of free ethylene oxide & 1,4 dioxane | ≤ | 0.001 | % |

| Limit of ethylene glycole & diethylene glycole | ≤ | 0.25 | % |

| Average molecular weight | 380 – 420 |

Polyethylene glycol 400 (PEG 400) is a low-molecular-weight polymer of ethylene oxide with an average molecular weight of approximately 400 g/mol. It appears as a clear, colorless, and odorless liquid commonly used as a solvent, plasticizer, and in pharmaceutical formulations.

🏭⚗️ Production

PEG 400 is produced by the polymerization of ethylene oxide with controlled reaction conditions to achieve the desired average molecular weight. The process involves ring-opening polymerization catalyzed by alkaline catalysts.

🔬 Properties

PEG 400 is a hygroscopic, water-soluble liquid with low toxicity. It is miscible with water and many organic solvents. It has a low viscosity compared to higher molecular weight PEGs and exhibits excellent solubilizing properties. PEG 400 is chemically stable, non-volatile, and non-irritating.

🧪 Applications

• Widely used as a solvent and vehicle in pharmaceutical formulations including topical, oral, and parenteral products.

• Acts as a plasticizer in manufacturing processes.

• Used in cosmetics as a humectant and skin-conditioning agent.

• Employed in industrial applications such as lubricants, antifreeze agents, and in the production of resins.